Overview

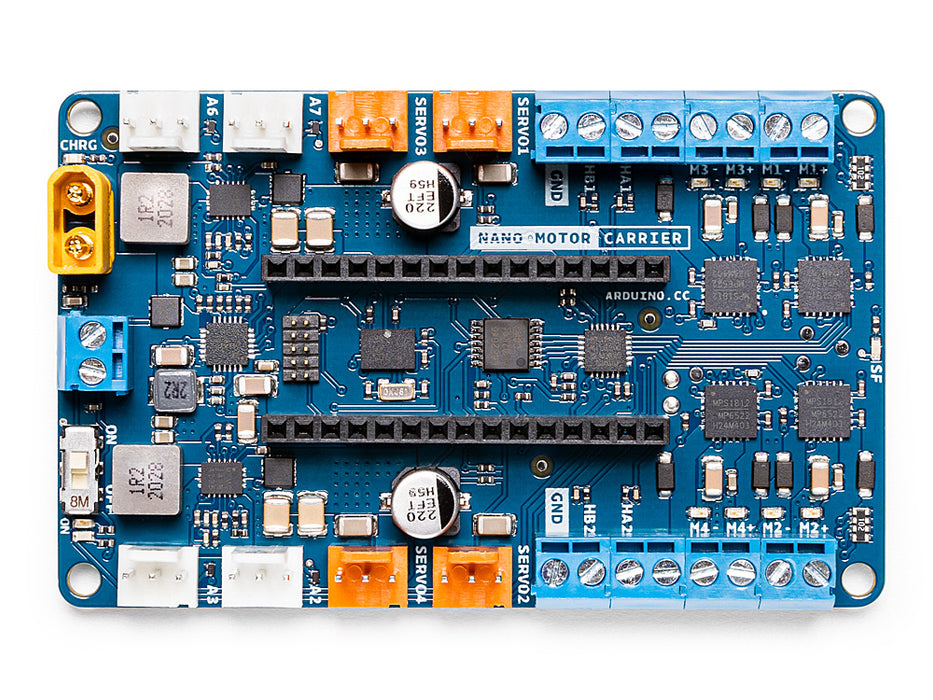

Nano Motor Carrier is the perfect add-on for the Nano 33 IoT board as it works to extend and power up its functionality.

Designed to facilitate motor control, Nano Motor Carrier takes care of the electronics required to control motors, allowing students to focus on prototyping and building their projects. It can also be used to connect other actuators and sensors via a series of 3-pin male headers. The board features are: on board 9 axis accelerometer, gyroscope and magnetometer. It includes a battery charger for single cell Li-ion batteries and it contains 2 ports for quadrature encoder counting.

To use the carrier, simply connect it to a Nano 33 board and attach the motors you need for your project. Once connected, attach the USB cable to the Nano 33 IoT. Download Arduino Motor Carrier library from the library manager and you’re all set up to start programming and controlling your motors using the motor drivers.

When working with motors, you need an external power source to feed the motor drivers and power the motors. You can do this by connecting a 1 cell Li-Ion battery to the battery connector or by using an external power source.

Tech specs

|

Microcontroller |

ATSAMD11 ( Arm Cortex-M0+ @48 Mhz) |

| Motor Drivers (x4) | MP6522 |

| Max Input voltage (power terminals) | 4V (1S Li-Ion Battery) |

| Max output current per motor driver | 500 mA |

| Motor driver output voltage | 12V |

| Over Temperature shutdown protection (for DC motor drivers) | Yes |

| Battery charging | Yes |

| Max battery charging current | 500mA (configurable) |

| Power terminals (connectors) | XT-30 and 2POS terminal block |

| Servo connector | 4 terminals |

| Encoder inputs | 2 ports |

| DC motor control | 4 ports |

| 3V digital/analog sensor input/output | 4 ports |

| IMU | BNO055 9axis Acc/Gyr/Mag |

Resources for Safety and Products

Manufacturer Information

The production information includes the address and related details of the product manufacturer.

Arduino S.r.l.

Via Andrea Appiani, 25

Monza, MB, IT, 20900

https://www.arduino.cc/

Responsible Person in the EU

An EU-based economic operator who ensures the product's compliance with the required regulations.

Arduino S.r.l.

Via Andrea Appiani, 25

Monza, MB, IT, 20900

Phone: +39 0113157477

Email: support@arduino.cc

Documentation

OSH: Schematics

Arduino Nano Motor Carrier is open-source hardware! You can build your own board using the following files:

Learn more

Get Inspired

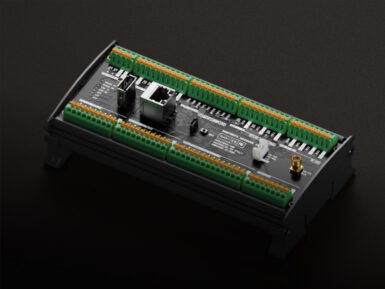

Arduino Pro is introducing a powerful new member of the Portenta product family, the Portenta Machine Control. It’s a fully-centralized, low-power, industrial control unit able to drive equipment and machinery. Plus, you can program it using the Arduino framework or other embedded development platforms. Thanks to its computing power, the Portenta Machine Control enables a wide range of predictive maintenance and AI use cases. It enables the collection of real-time data from the factory floor, while supporting remote control of equipment, including from the cloud. Key benefits include: Shorter time-to-marketEnhance existing productsAdd connectivity for monitoring, as well as controlEach I/O pin can be configured, so you can tailor it to your needsMake equipment smarter, as well as AI-readyProvide security and robustness from the ground upOpen new business model opportunities (such as servitization)Interact with your equipment with advanced human-machine interfaces (HMI)Modular design for adaptation, expansion and upgrades Business as a Service The Portenta Machine Control allows companies to enable new business-as-a-service models. You can monitor customer usage of equipment for predictive maintenance while gathering valuable production data. The device enables industry standard soft-PLC control. Because of this, it's able to connect to a range of external sensors and actuators. For example, the following options are all available. Isolated digital I/O, 4-20mA compatible analog I/OThree configurable temperature channelsDedicated I2C connector. Multiple choices are available for network connectivity, including USB, Ethernet and WiFi and BLE. Furthermore, it offers impressive compatibility through industry specific protocols such as RS485. All I/O are protected by resettable fuses, but on-board power management ensures maximum reliability in harsh environments. The Portenta Machine Control core runs an Arduino Portenta H7