Overview

The possibilities are infinite with this Kit of essential Arduino components.

Prototype with the solderless breadboard to control sensors and actuators with Arduino.

You'll need some materials of your own as your progress through your project to make it really unique.

At the very least, you will need a 9V battery and a computer, but we recommend keeping some basic craft supplies handy - like paper, tape, markers and scissors.

Use the Arduino IDE and Arduino Project Hub for tutorials and projects!

Tech specs

The Kit includes:

- 1 USB cable

- 1 Breadboard

- 70 Solid core jumper wires

- 1 LED (Green)

- 1 LED (Yellow)

- 3 LEDs (Red)

- 5 Capacitors (10nF)

- 5 Capacitors (100nF)

- 5 Capacitors (100uF)

- 2 Transistors (BC547)

- 2 Optocouplers (4N35)

- 1 Potentiometer (10k ohm)

- 1 Mosfet Transistor (IRF520)

- 1 Diode (1N4007)

- 1 Thermistor (4,7k ohm)

- 1 Piezo Buzzer

- 5 Push Buttons

- 2 Tilt Sensors

- 1 Photoresistors

- 5 Resistors (330k ohm)

- 5 Resistors (10k ohm)

- 5 Resistors (2.2k ohm)

- 10 Resistors (220 ohm)

- 1 Male Headers Pins (40x1)

The Arduino UNO Rev3 board is nor included.

Resources for Safety and Products

Manufacturer Information

The production information includes the address and related details of the product manufacturer.

Arduino S.r.l.

Via Andrea Appiani, 25

Monza, MB, IT, 20900

https://www.arduino.cc/

Responsible Person in the EU

An EU-based economic operator who ensures the product's compliance with the required regulations.

Arduino S.r.l.

Via Andrea Appiani, 25

Monza, MB, IT, 20900

Phone: +39 0113157477

Email: support@arduino.cc

Get Inspired

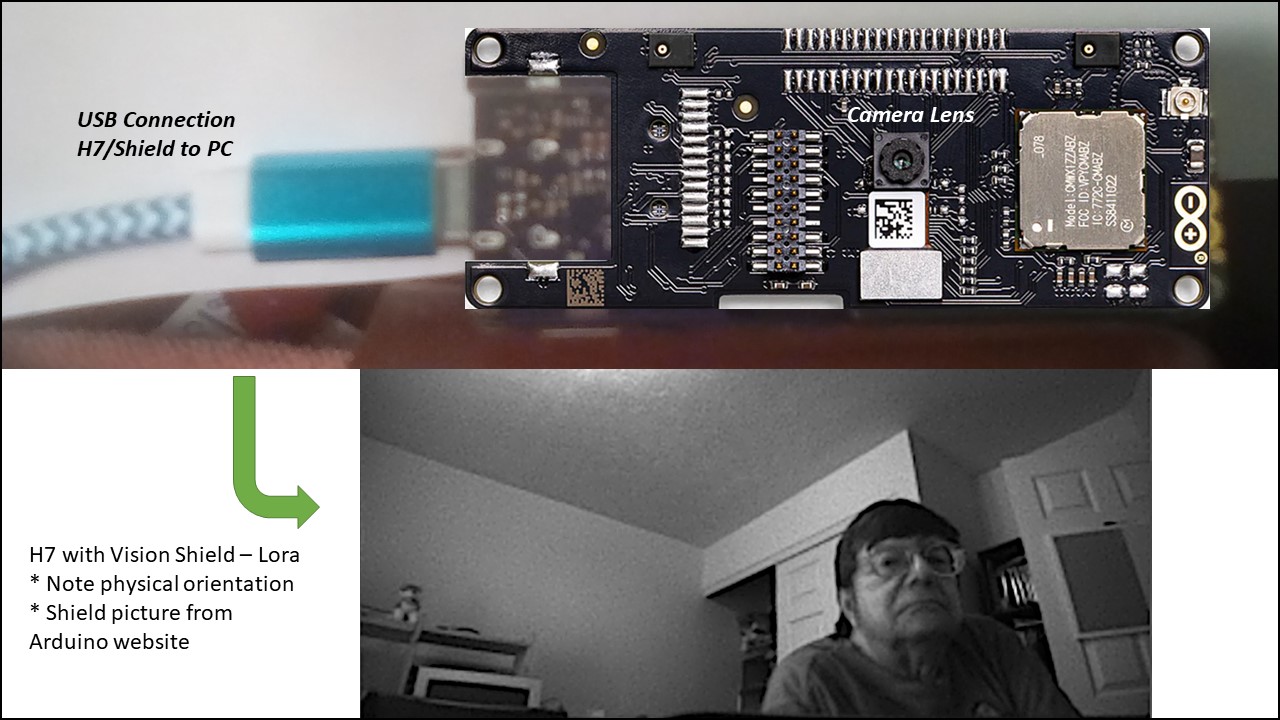

Begins a process of combining Portenta H7 with Vision Shield – LoRa by acquiring, sending, and displaying a camera image via USB/Serial connection.

It’s time to catch up on all things LoRaWAN® and low-power IoT! Our team is looking forward to returning to The Things Conference this year, joining all LoRa® key players in Amsterdam on September 21st-22nd. Our experts will be showcasing new products and applications relevant to the technology that is putting the “smart” in smart cities, smart agriculture, smart logistics, and more. Indeed, with IoT’s huge growth potential in both B2B and B2C applications, LoRaWAN® is stepping up as one of the technologies of the future. Already established as the low-power connectivity choice, according to The Things Network it is reaping the benefits of innovations that increase efficiency even further – and is poised to support ESG (environmental, social and governance) goals with reduced energy consumption and secure data transmission. LoRaWAN® novice, or expert? We’ve got you covered Whether you are just realizing the potential of LoRaWAN® or have been a fan of it since day one (like us!), we’ll have something for you to discover at our booth at The Things Conference: Looking for an entry-level option? The Arduino MKR WAN 1310 offers you the renowned versatility of the practical and cost-effective MKR family and adds LoRa® connectivity to projects requiring low power.Ready to take it up a notch? The solution for advanced applications requiring sturdy computational power is to boost Arduino Pro’s Portenta H7 module (in any of its three variants) with the capability to run embedded computer vision applications, connect wirelessly via LoRa® to the Arduino Cloud (or third-party infrastructure), and activate systems upon the detection of sound events. How? With the Portenta Vision Shield LoRa®, of course!Feel the need for high performance? Pair the Portenta Max Carrier with a Portenta X8 module to add LoRa® connectivity to your project, transforming your robust SOM into a single-board computer or reference design enabling edge AI for