J-Link PLUS Compact

USB powered JTAG debug probe supporting a large number of CPU cores.

Based on a 32-bit RISC CPU, it can communicate at high speed with the supported target CPUs.

SEGGER J-Link PLUS Compact is used around the world in tens of thousand places for development and production (flash programming) purposes.

Overview

Get the SEGGER J-Link PLUS Compact debug probe: a compact version of the J-Link PLUS. Mounts securely & unobtrusively into development and end user equipment.

Based on 32-bit RISC CPU, it communicates at high speed with supported target CPUs.

Thanks to a small size with two mounting holes, it can be placed into existing equipment housings.

Space can also be reserved for direct-to-PCB mounting.

All major IDEs (Eclipse & GDB-based IDEs) support J-Link debug probes, as does SEGGER Embedded Studio. 500,000 J-Links have been shipped so far, making this probably the most popular debug probe on the market for Arm cores and the de-facto standard.

Further Advantages

The SEGGER J-Link PLUS Compact has a built-in VCOM functionality and integrated licenses for unlimited breakpoints in flash memory, RDI/RDDI and J-Flash. It supports direct download into RAM and flash memory. It has a broad range of supported microcontrollers and CPUs.

Box Contents

- SEGGER J-Link PLUS Compact debug probe

- Micro USB cable

- 1" 20-pin ribbon cable (18 cm)

- Includes free software updates and one year of email support.

SEGGER J-Link debuggers are the most popular choice for optimizing the debugging and flash programming experience.

Documentation

Debugging with the Arduino IDE 2.0

Learn how to set up a Zero board, J-Link and Atmel-ICE debuggers with the Arduino IDE 2.0, and how to debug a program.

Using the Segger J-Link debugger with the MKR boards

Learn how to set up a MKR board with the Segger J-link debugger.

Get Inspired

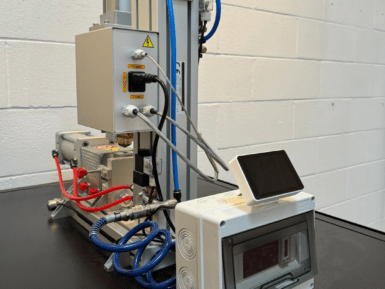

… and equipment status from anywhere with an Internet connection. Additionally, the Arduino Opta WiFi is equipped with RS485 communication capabilities, enabling seamless integration with an external power meter – in our case, a Finder model. This provides valuable insights into energy consumption, production output, material usage, and equipment health. The collected data is then analyzed through dedicated dashboards, offering information about operational efficiency and potential issues. By leveraging this data, businesses can proactively schedule maintenance and repairs, minimizing downtime and optimizing production processes. Retrofitting for a connected future Many businesses today can retrofit existing machinery to embrace the benefits of connectivity and automation. Our demo provides a practical example of how common industrial equipment can become smarter, more efficient, and easier to manage. From remote monitoring and control to power metering and predictive maintenance, retrofitting offers a sustainable way to modernize industrial infrastructure. Unlocking potential across industries Moreover, the versatility of Arduino’s open-source ecosystem ensures that this solution can be adapted and applied to a wide range of existing machines and equipment, enhancing their operation effectively – whether in manufacturing, logistics, or any other industry relying on machinery. To learn more about how you can leverage Arduino technology to upgrade your infrastructure and achieve tangible results, contact us today. Let us help you unlock the full potential of your industrial assets with practical, cost-effective solutions.