Grove - 6-Axis Accelerometer & Gyroscope

Sold outThe Grove - 6-Axis Accelerometer & Gyroscope is a cost-effective Grove sensor integrated with a 3-axis digital accelerometer and a 3-axis digital gyroscope.

Overview

It has a low power consumption digital chip LSM6DS3 and power supply regulator which features high sensitivity and low noise interference. It can be configured to different levels of sensitivity to acceleration and can use different ranges of angular rate measurement. It is provided with a detailed SDK, which makes the prototyping process quick and easy.

This product is good for applications where tilt, motion, and tap sensing is needed.

Features:

- Grove interfaced and cost-effective.

- Digital-output for 6 DOF motion data.

- ±2/±4/±8/±16 g full scale leaner acceleration sensing range for various environment.

- ±125, ±245, ±500, ±1000, ±2000 degree per seconds(dps) for angular rate measurement range makes it versatile.

- A Detailed SDK for easy programming.

- Regulated power supply for reliable data to be collected.

- Programmed interrupts for different event.

Tech specs

- Analog supply voltage: 5V/3.3V(DC)

- Power consumption: 0.9 mA in combo normal mode and 1.25 mA in combo high-performance mode up to 1.6 kHz

- Linear acceleration measurement range ±2/±4/±8/±16 g full scale (typical value)

- Angular rate measurement range ±125, ±245, ±500, ±1000, ±;2000 dps(typical value)

- Linear acceleration sensitivity 0.061(FS = ±2), 0.122(FS = ±4), 0.244(FS = ±8), 0.488(FS = ±16) mg/LSB

- Angular rate sensitivity 4.375(FS = ±125), 8.75(FS = ±245), 17.50(FS = ±500), 35(FS = ±1000), 70(FS = ±2000)

Technical Details

|

Dimensions |

140mm x 85mm x 10.3mm |

|

Weight |

G.W 6g |

Get Inspired

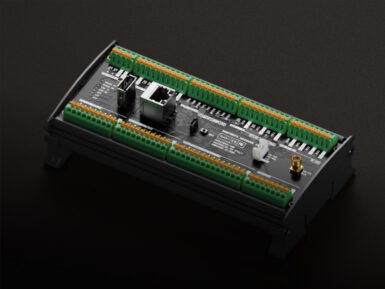

Arduino Pro is introducing a powerful new member of the Portenta product family, the Portenta Machine Control. It’s a fully-centralized, low-power, industrial control unit able to drive equipment and machinery. Plus, you can program it using the Arduino framework or other embedded development platforms. Thanks to its computing power, the Portenta Machine Control enables a wide range of predictive maintenance and AI use cases. It enables the collection of real-time data from the factory floor, while supporting remote control of equipment, including from the cloud. Key benefits include: Shorter time-to-marketEnhance existing productsAdd connectivity for monitoring, as well as controlEach I/O pin can be configured, so you can tailor it to your needsMake equipment smarter, as well as AI-readyProvide security and robustness from the ground upOpen new business model opportunities (such as servitization)Interact with your equipment with advanced human-machine interfaces (HMI)Modular design for adaptation, expansion and upgrades Business as a Service The Portenta Machine Control allows companies to enable new business-as-a-service models. You can monitor customer usage of equipment for predictive maintenance while gathering valuable production data. The device enables industry standard soft-PLC control. Because of this, it's able to connect to a range of external sensors and actuators. For example, the following options are all available. Isolated digital I/O, 4-20mA compatible analog I/OThree configurable temperature channelsDedicated I2C connector. Multiple choices are available for network connectivity, including USB, Ethernet and WiFi and BLE. Furthermore, it offers impressive compatibility through industry specific protocols such as RS485. All I/O are protected by resettable fuses, but on-board power management ensures maximum reliability in harsh environments. The Portenta Machine Control core runs an Arduino Portenta H7