Grove - 3-Axis Digital Accelerometer (±16g)

Sold out3-Axis Digital Accelerometer is the key part in projects where importance is placed on orientation, gesture and Motion detection.

Overview

This 3-Axis Digital Accelerometer(±16g) is based on the low power consuming IC ADXL345. It features up to 10,000g high shock survivability and has a configurable samples per second rate. For applications that don’t require too large measurement range, this is a great choice because it’s durable, energy saving and cost-efficient.

Tech specs

-

Working voltage: 3.0 - 5.5V

-

Test Range: ±16

-

Sensitivity: 3.9mg / LSB

-

Standby Current: 0.1μA(Under stand mode Vcc = 2.5 V (typical))

-

10000 g high shock survivability

-

ECOPACK®RoHS and “Green” compliant

Get Inspired

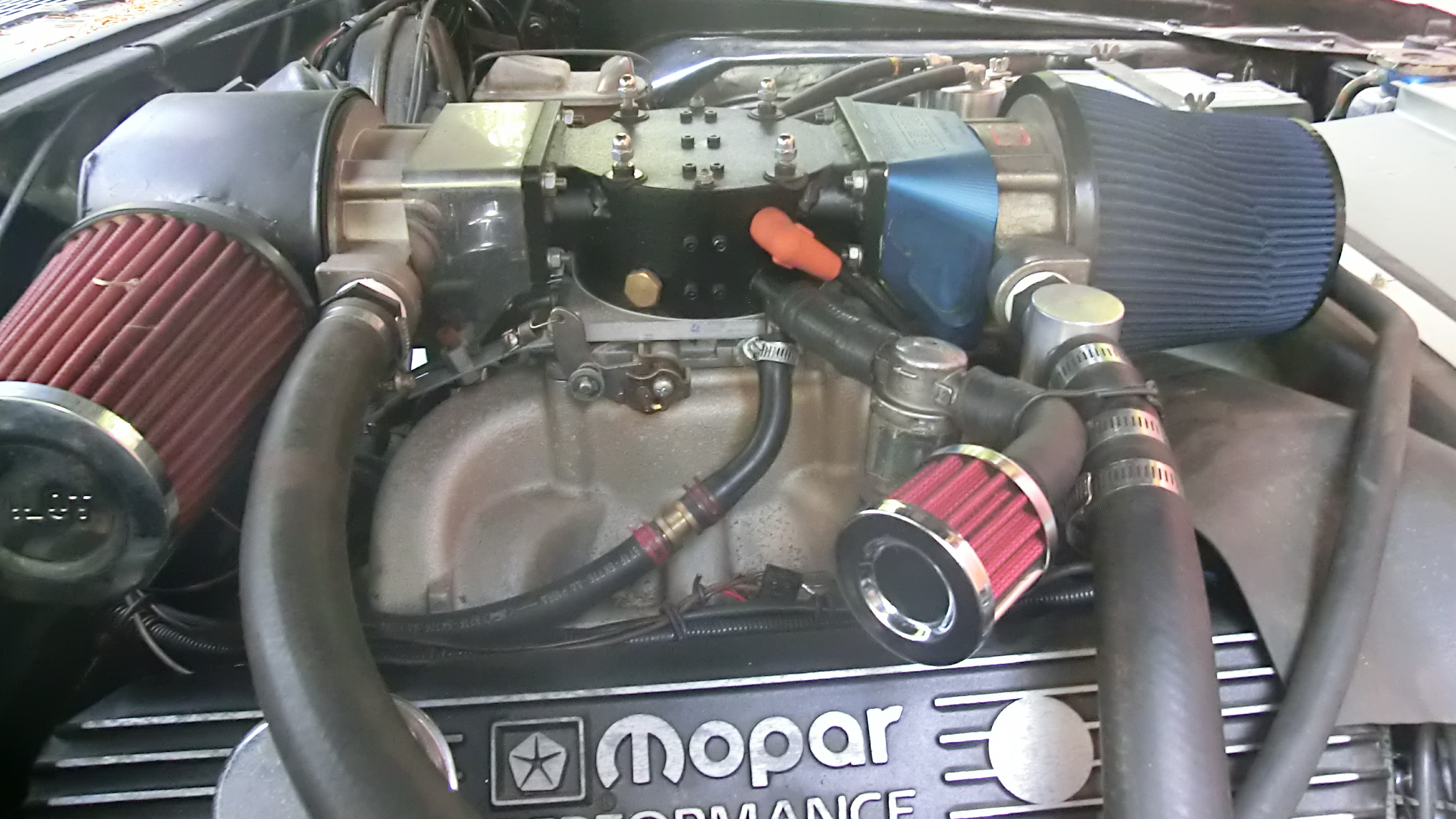

Control the air/fuel mixture for a better fuel economy of a engine with a Arduino Nano.

When you want to paint the walls in your bedroom that very specific shade of Misty Irish Green, all you have to do is head to your local hardware store and have them scan the corresponding card. The paint-mixing machine will then add the pigment to a white base and, a few minutes later, you have that exact color. So, shouldn’t you be able to do the same thing with acrylic paint for hobby purposes? Now you can, thanks to the “Color By Code” machine designed by Caltech students Frida Moreno and Asmat Kaur Taunque. Moreno and Taunque built Color By Code for a class project and it is, essentially, a hobby version of those hardware store paint-mixers intended for acrylic paint. As is the standard across many industries that deal with pigments, paint, and printing, this works using CMYK (cyan, magenta, yellow, key) color mixing. Here, the key is black and the machine takes an input color value for each component, then dispenses the paint in those ratios to achieve the desired hue. That all happens under the control of an Arduino Nano Every board. That operates peristaltic pumps, via L298N motor drivers, that dispense each color. Afterwards, a flushing procedure clears the lines before the next mix. The pumps fit into a 3D-printed stand, with the hoses dropping below to a waiting container. At this time, the user must set the color values through serial commands. But the team hopes to create a Bluetooth app in the future. They also plan to add a weight sensor, which would improve the machine’s accuracy.