NFC/RFID reader with two transponders

NFC/RFID reader/writer with 1 status LED, antenna integrated on PCB, I²C, SPI, and HSU (High Speed UART) communication interface

Overview

It can function as an RFID card reader/writer, NFC reader with Android smartphone and in wireless mode with two identical devices.

It can be used with Arduino to create access control devices.

The package includes the reader, a keychain transponder, a card transponder and connection cables.

Tech specs

- Power supply: from 3.3 V to 5 V

- Compact and easy to integrate into your project

- Supports interface: I²C, SPI and HSU (High Speed UART), selectable via dip-switch

- Supports RFID read/write, P2P communication between two identical modules, NFC with Android smartphone

- Supports RFID read/write:

- Mifare 1k, 4k, Ultralight, and DesFire cards

- ISO/IEC 14443-4 cards such as CD97BX, CD light, Desfire, P5CN072 (SMX)

- Innovision Jewel cards such as IRT5001 card

- FeliCa cards such as RCS_860 and RCS_854 - Reading distance (mm): max. 50-70

- Dimensions (mm): 43x41x4

Conformities

Get Inspired

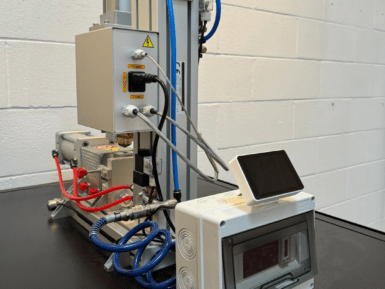

… and equipment status from anywhere with an Internet connection. Additionally, the Arduino Opta WiFi is equipped with RS485 communication capabilities, enabling seamless integration with an external power meter – in our case, a Finder model. This provides valuable insights into energy consumption, production output, material usage, and equipment health. The collected data is then analyzed through dedicated dashboards, offering information about operational efficiency and potential issues. By leveraging this data, businesses can proactively schedule maintenance and repairs, minimizing downtime and optimizing production processes. Retrofitting for a connected future Many businesses today can retrofit existing machinery to embrace the benefits of connectivity and automation. Our demo provides a practical example of how common industrial equipment can become smarter, more efficient, and easier to manage. From remote monitoring and control to power metering and predictive maintenance, retrofitting offers a sustainable way to modernize industrial infrastructure. Unlocking potential across industries Moreover, the versatility of Arduino’s open-source ecosystem ensures that this solution can be adapted and applied to a wide range of existing machines and equipment, enhancing their operation effectively – whether in manufacturing, logistics, or any other industry relying on machinery. To learn more about how you can leverage Arduino technology to upgrade your infrastructure and achieve tangible results, contact us today. Let us help you unlock the full potential of your industrial assets with practical, cost-effective solutions.