Overview

The RCWL-0516 is particularly suitable as an alternative to using a PIR motion sensor.

When it detects a moving object, the output changes from a low logic level to a high level (3.3 volts). Appropriately interfaced (Arduino, Fishino or other), it can be used for the automatic opening of electric doors and gates, automatic lighting.

Detection range is about 9 meters.

Tech specs

- Power supply: from 4 volts to 28 volts

- Consumption: typical 2.8 mA; max. 3 mA

- Detection distance: from 5 to 9 meters

- Transmission power: typical 20 mW; max. 30 mW

- Output voltage and current: 3.2-3.4 volts - 100 mA

- Operating temperature: from -20°C to +80°C

- Pin definition: 3V3: 3.3 volt output voltage

- GND: negative power supply

- OUT: when it detects a moving object, it changes from a low level to a high level (3.3 volts)

- VIN: positive power supply from 4 volts to 28 volts

- CDS: if kept low, less than 0.7 volts, the output will always be low even in the presence of motion

Conformities

Get Inspired

An interactive polyphonic wavetable synthesiser for the Arduino GIGA & Display Shield

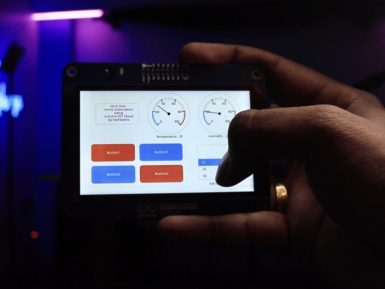

In a previous video about controlling household appliances and lighting fixtures from the Arduino Cloud, Sachin Soni of the techiesms YouTube channel designed a custom PCB that allows an Arduino Nano ESP32 to toggle a series of relays. But since then, he realized that his project needed a faster and more permanent method of getting to the controls, which led him to build a complete home automation dashboard using solely Arduino hardware. Soni opted for the new Arduino GIGA Display Shield since it contains a 3.97” RGB touchscreen with support for up to five simultaneous touch points and an array of sensors if the functionality were to ever be expanded. On the back, an Arduino GIGA R1 WiFi was attached to act as the display’s controller and leverage its Wi-Fi capabilities to communicate with the system’s Arduino Cloud variables. The final step in this project involved creating a software-defined graphical user interface (GUI) complete with toggleable buttons for the lights, dials to indicate temperature/humidity levels, and a way to select the fan’s speed from an array of values. Soni was able to finish most of the groundwork by utilizing the LVGL library and its highly customizable GUI components. After laying out the buttons and dials, synchronizing Cloud variables, and connecting their event handlers to value updates, Soni had a functional tablet that could wirelessly manage his appliances from anywhere.