Overview

The package includes:

- 20 pcs - 6x6x4.3 mm

- 20 pcs - 6x6x5 mm

- 20 pcs - 6x6x6 mm

- 20 pcs - 6x6x7 mm

- 20 pcs - 6x6x8 mm

- 20 pcs - 6x6x9.5 mm

- 20 pcs - 6x6x11 mm

- 15 pcs - 6x6x12 mm

- 15 pcs - 6x6x13 mm

- 10 pcs - 6x6x14 mm

Tech specs

- Category: 12 Vdc - 50 mA

- Insulation resistance: > 100 Mohm - 250 Vdc

- Contact resistance: <100mohm

- Soldering temperature: 255°C max. 5 seconds

- Average mechanical life: 500,000 cycles

- Average electrical life: 300,000 cycles

- Operating temperature: -25°C to +70°C

Get Inspired

Exploring the digital twin synthetic data generation and AI-oriented advancements on real-world shipping operations w/ NVIDIA Omniverse.

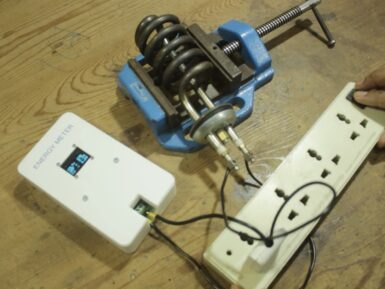

The primary appeal of microcontrollers is their versatility. They are, essentially, the embedded equivalent of computers — general purpose devices that can perform a wide range of functions. And to get the most out of a microcontroller, you’ll also want connectivity suitable for your application. That’s why we released the Arduino Nano Matter and YouTuber Mr Innovative has shared a great video illustrating how easy it is to build an energy meter using this new development board. The Nano Matter is based on the powerful Silicon Labs MGM240S, which has an Arm Cortex-M33 processor and support for a number of wireless connectivity options, including 802.15.4 (Zigbee and Thread), Bluetooth® Low Energy 5.3, Bluetooth® Mesh, and Matter. That makes the Nano Matter perfect for smart home and other Internet of Things applications. To demonstrate that, Mr Innovative created an energy meter that would be useful to many people around the world. This unit monitors the power flowing to any device or appliance connected to mains AC power. It displays information about that power consumption on a small OLED screen, and also sends the data over Bluetooth to a connected smartphone for logging. The Nano Matter can’t monitor mains AC voltage directly, so Mr Innovative used a ZMCT103C current transformer for the job. The Arduino receives its power from a 9V battery and the components fit inside a 3D-printed enclosure. A printed sticker label gives that a nice, smooth top finish.