Overview

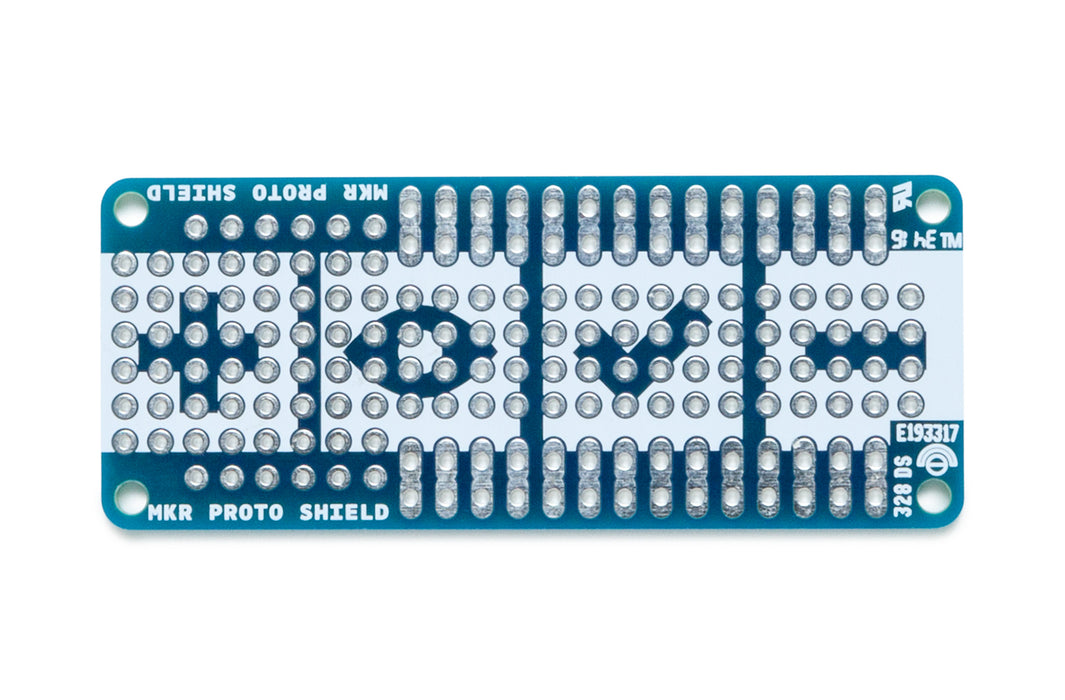

The MKR Proto Shield is a prototyping shield designed for your MKR board. This shield easily plugs onto your MKR using its provided female/male headers, and offers a duplicate breakout for each pin on the board along with many solderable through-holes on a standard 0.1” grid (2.54mm).

Tech specs

| Digital I/O Pins | 21 |

| PWM Digital I/O Pins | depending on the board |

| Analog Input Pins | 7 |

| Analog Output Pins | depending on the board |

| DC Current per I/O Pin | depending on the board |

| DC Current for 3.3V Pin | depending on the board |

| DC Current for 5V Pin | depending on the board |

| Lenght | 61.5 mm |

| Width | 25 mm |

| Weight | 13 |

Conformities

Resources for Safety and Products

Manufacturer Information

The production information includes the address and related details of the product manufacturer.

Arduino S.r.l.

Via Andrea Appiani, 25

Monza, MB, IT, 20900

https://www.arduino.cc/

Responsible Person in the EU

An EU-based economic operator who ensures the product's compliance with the required regulations.

Arduino S.r.l.

Via Andrea Appiani, 25

Monza, MB, IT, 20900

Phone: +39 0113157477

Email: support@arduino.cc

Documentation

OSH: Schematics

The MKR Proto Shield is open-source hardware! You can build your own board using the following files:

EAGLE FILES IN .ZIP SCHEMATICS IN .PDFGet Inspired

Want to build a DIY project where you need to sense movement within a certain range then HC-SR501 Passive Infrared (PIR) sensor is perfect. Learn how to use PIR sensor to detect motion of person or animal.