CAN-BUS Shield v2

Sold outWith its long travel distance, great communication speed and high reliability, CAN-BUS is one of the most common industrial bus.

Overview

It is commonly found on modern machine tools and as an automotive diagnostic bus.

Thanks to the CAN-BUS, makers are able to hack their cars!

It adopts MCP2515 CAN-BUS controller with SPI interface and MCP2551 CAN transceiver to give you Arduino CAN-BUS capability. Default pinout is OBD-II and CAN standard pinout can be selected by switching jumpers on DB9 interface.

Moreover, it has the TF card slot for data storage and the CS pin that can be set to D4 or D5.

The INT pin can also be set to D2 or D3 by switching jumpers on the back of the shield.

CAN-BUS Shield Works perfectly with Arduino UNO (ATmega328), Arduino Mega (ATmega1280/2560) as well as Arduino Leonardo (ATmega32U4).

Features:

-

Implements CAN V2.0B at up to 1 Mb/s

-

Industrial standard 9 pin sub-D connector

-

OBD-II and CAN standard pinout selectable.

-

Changeable chip select pin

-

Changeable CS pin for TF card slot

-

Changeable INT pin

-

Screw terminal that easily to connect CAN_H and CAN_L

-

Arduino Uno pin headers

-

2 Grove connectors (I2C and UART

-

SPI Interface up to 10 MHz

-

Standard (11 bit) and extended (29 bit) data and remote frames

-

Two receive buffers with prioritized message storage

Conformities

Get Inspired

Another Slot Car Lap Counter, but if I did it anyone can do!

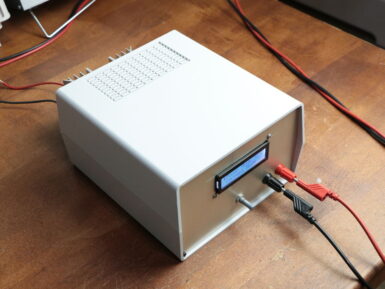

If you need a device which draws a certain amount of current and power for testing, then GreatScott! has just the solution. His project uses an Arduino Nano, along with a separate IC and a voltage divider, to measure both current and voltage input from the power source. It then employs this data to properly adjust a MOSFET, dissipating the correct amount of voltage and power as required. Interface is handled via a rotary encoder and a 16x2 I2C LCD display, and the electronics are housed in a solid-looking enclosure. As seen in the video below, the adjustable constant load features an impressively large heat sink, needed to take care of the 30V and 20A that the setup is capable of drawing.